Applications

We partner with metal manufacturers specializing in additive manufacturing, laser cladding, thermal spray, hot isostatic pressing, metal injection molding, electron beam and more.

Our premium metal powders support essential industries such as aerospace, space, defense, oil & gas, automotive, and other advanced manufacturing sectors, delivering high performance that promotes sustainability and excellence in manufacturing

Explore Applications:

Additive Manufacturing

Additive manufacturing (AM)is exceptionally versatile, allowing for the creation of highly complex and customized parts that would not be possible with subtractive methodologies. AM minimizes material waste by building components layer by layer, reducing costs and environmental impact. It enables rapid prototyping, on-demand production, and the consolidation of multiple parts into a single, intricate design, promoting lightweighting and resource efficiency. With its ability to push the boundaries of design and innovation – while reducing lead times and costs, additive manufacturing is transforming industries and driving new frontiers in manufacturing excellence.

Typical markets: Aerospace, Automotive, Defense, Energy, Oil & Gas, Medical

The Continuum Advantage:

- Cost-Effective Production: Reduce reliance on expensive powders and streamline your budget with our competitively priced reclaimed materials

- Sustainable Manufacturing: Meet sustainability goals with powders made from 100% reclaimed metals, significantly lowering environmental impact

- Uncompromised Performance: Our high-quality powders guarantee exceptional printability and consistent results for demanding AM applications

Metal Injection Molding (MIM)

Metal Injection Molding is unique for its ability to manufacture complex shapes cost-effectively, reducing waste and post-processing operations. It supports a wide range of metal alloys, making it suitable for diverse applications across various industries. With its capacity to produce parts with high strength and intricate geometries, MIM is a game-changer in the realm of metal manufacturing, delivering top-notch performance, cost-efficiency, and design versatility.

Typical markets: Aerospace, Automotive, Energy, Defense, Medical

The Continuum Advantage:

- Enhanced Part Quality: Achieve superior part density and mechanical properties with our consistent, high-purity powders

- Optimized Production Efficiency: Improve flowability and packing characteristics for efficient MIM processing

- Sustainable Choice for Manufacturers: Reduce reliance on virgin materials and meet sustainability goals through our reclaimed metal powders

Hot Isostatic Pressing (HIP)

Hot isostatic pressing (HIP) is a manufacturing process that is used to reduce the porosity and increase density of materials. The process subjects the target materials to both elevated temperature and pressure in a high-pressure containment vessel. As the chamber is heated, the pressure increases, and the resultant pressure compresses and densifies the subject material. Since the pressure is uniform in all directions, the term isostatic is applied.

Typical markets: Aerospace, Defense, Space, Automotive, Energy, Medical

The Continuum Advantage:

- Improved Microstructure: Our fully-melted powders contribute to a denser, more uniform microstructure for enhanced performance in HIP applications

- Cost-Effectiveness: Achieve high-quality HIP results at a lower price point through our competitively priced reclaimed powders

- Sustainable Manufacturing: Make a positive environmental impact by choosing powders made from 100% reclaimed materials

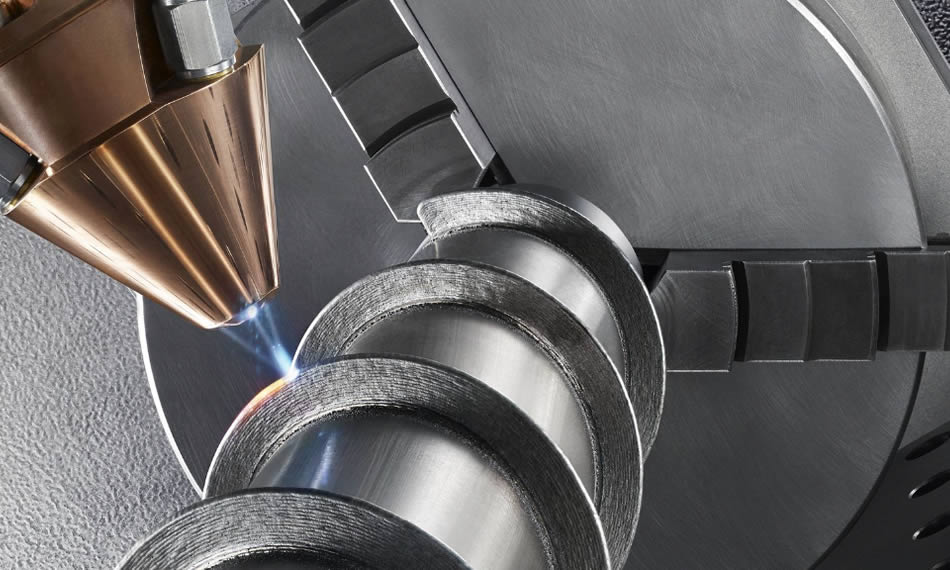

Laser Cladding

This cutting-edge technique empowers the creation of highly precise and durable metal components with unmatched speed and efficiency. By applying laser energy to deposit material layer by layer, it enhances material properties, making parts more resilient and wear-resistant. With its ability to repair and refurbish worn parts and add features to existing components, laser cladding offers a sustainable and cost-effective solution for industries seeking top-notch performance and longevity in their metal products.

Typical markets: Aerospace, Automotive, Energy, Oil & Gas, Defense

The Continuum Advantage:

- Exceptional Bond Strength: Achieve superior bond strength & wear resistance with our high-quality powders for laser cladding applications

- Cost Savings: Reduce material costs while maintaining performance with our competitively priced reclaimed powders

- Sustainable Choice: Reduce your environmental footprint by using powders made from 100% reclaimed materials

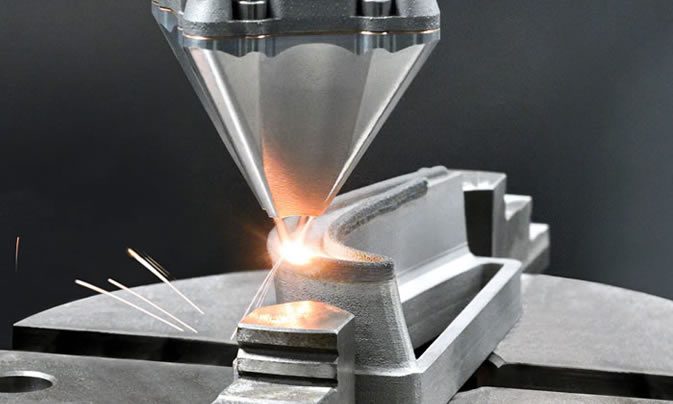

Direct Energy Deposition (DED)

(DED) is a versatile additive manufacturing process that enables the creation of complex and high-performance metal components with exceptional precision. By simultaneously melting powder material and depositing it layer by layer, DED allows for the fabrication of intricate geometries and the integration of multiple materials within a single build. This technology not only accelerates production times but also enhances the mechanical properties of parts, making them stronger and more durable. Ideal for both prototyping and large-scale manufacturing, DED offers a flexible and cost-effective solution for industries aiming to innovate and optimize their metal product offerings.

Typical Markets: Aerospace, Automotive, Energy, Oil & Gas, Defense

The Continuum Advantage:

- Superior Flowability and Meltability: Our powders are engineered for optimal flow and melt behavior in DED processes, ensuring smooth deposition and consistent results

- Cost-Effective Approach: Achieve high-quality DED results at a lower cost through the use of our competitively priced reclaimed powders

- Environmentally Responsible Manufacturing: Align your DED processes with sustainability goals – 99.7% emissions reduction

Powder Coating

Powder Coating is an advanced finishing technique that applies a protective and decorative layer to metal surfaces with exceptional uniformity and durability. Using electrostatic spray application, fine powder particles are evenly distributed and then cured under heat to form a robust, long-lasting coating. This method not only enhances the aesthetic appeal of components but also provides superior resistance to corrosion, wear, and environmental factors. Ideal for both new manufacturing and refurbishment projects, powder coating offers a sustainable and cost-effective solution for industries aiming to improve the longevity and performance of their metal products.

Typical Markets: Aerospace, Automotive, Consumer Goods, Construction, Electronics

The Continuum Advantage:

- Improved Coating Efficiency: Our powders offer excellent flowability and packing density for efficient powder coating applications, reducing waste

- Cost-Effective Coating Solutions: Achieve high-quality powder coatings at a lower price point with our competitively priced reclaimed powders

- Sustainable Choice for Manufacturers: Reduce reliance on traditionally sourced materials and contribute to a greener production process

Redefining Metal Powder for

Sustainable, Cost-Effective Manufacturing

Discover the difference