Premium Metal Powders

OptiPowders

Continuum’s advanced portfolio includes high-performance titanium, nickel alloys, maraging steel, and stainless steel, all precisely engineered for advanced manufacturing. With a focus on sustainability and certified quality, our powders help manufacturers reduce costs and carbon emissions while maintaining superior performance. From custom alloy development to circular metal economy solutions, we provide a comprehensive approach to sustainable manufacturing.

OptiPowder

Ni718

OptiPowder

Ni625

OptiPowder

Ni7208

OptiPowder

M247/247LC

OptiPowder

Ti64

OptiPowder

SS316

OptiPowder

SS17-4PH

OptiPowder

C300

Full-Service Powder Management

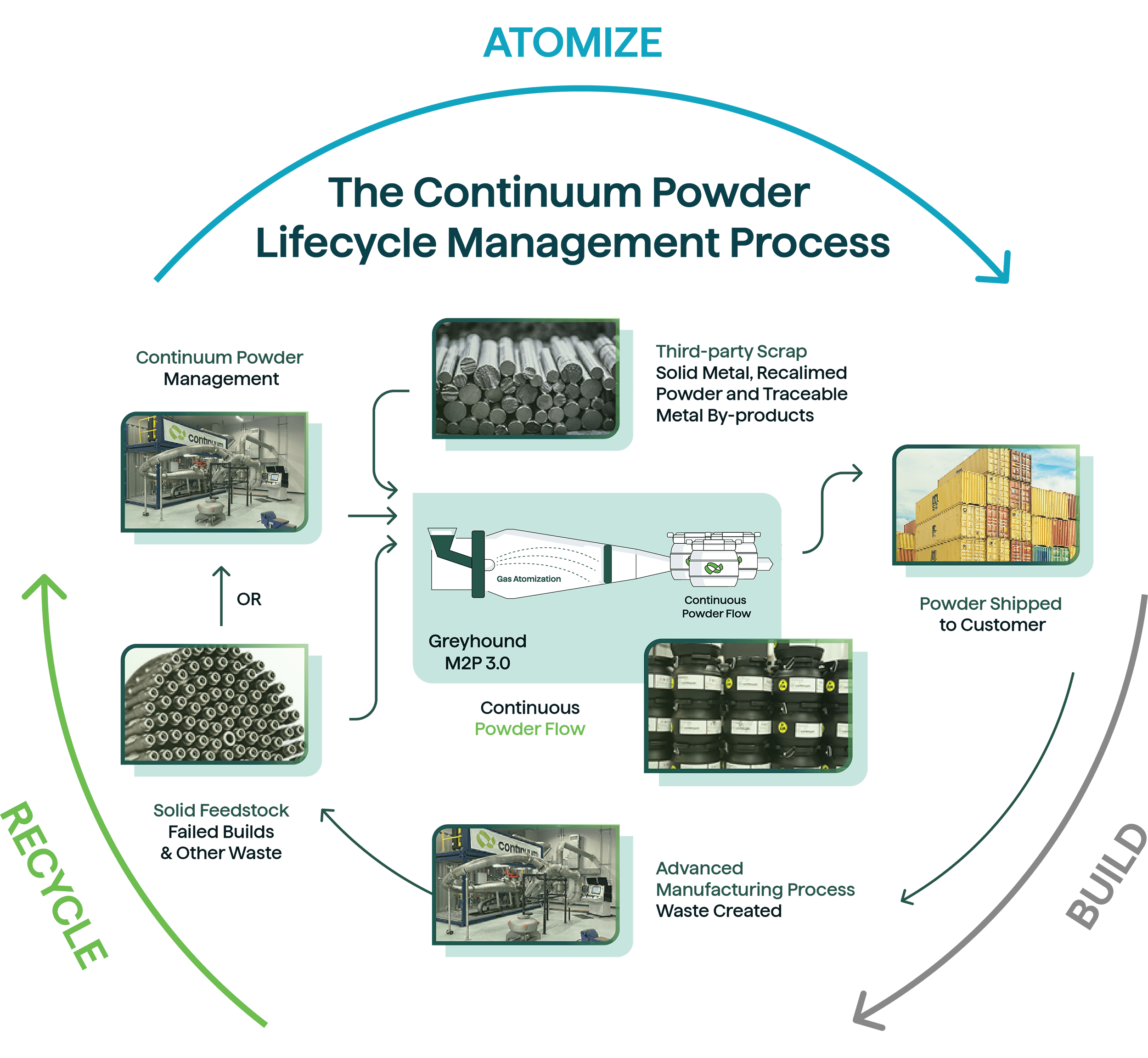

At Continuum Powders, we go beyond supplying high-quality, sustainable metal powders—we offer a comprehensive powder management solution that supports every stage of your advanced manufacturing process. Our full-service powder management ensures that your materials are optimized for performance, sustainability, and cost-effectiveness.

What We Offer

Material Sourcing & Certification

We provide ASTM-grade reclaimed powders, certified for consistency, purity, and performance, meeting the highest standards.

On-Site Powder Handling

Our experts assist with storage, handling, and monitoring of metal powders to maintain optimal quality and reduce contamination risks.

Lifecycle Management & Reclamation

We implement a circular approach by reclaiming used powder, reprocessing it through our proprietary technologies, and returning it to you as premium, ready-to-use powder.

Quality Assurance & Testing

Each batch undergoes rigorous testing to guarantee repeatability and adherence to strict specifications, ensuring that your production runs smoothly and reliably.

Consulting & Technical Support

Our team of specialists works closely with you to fine-tune powder characteristics and process parameters, maximizing efficiency and minimizing waste.

The Continuum Advantage

With full-service powder management, you can seamlessly integrate reclaimed powders into production workflows while reducing environmental impact & operational costs.

Metal Reclamation

Our Reclamation Process: Turning Used Material into High-Quality Powder

At Continuum Powders, we transform end-of-life metal components into premium, ASTM-grade powders through our advanced reclamation process. By converting previously used materials back into high-performance powders, we support a circular economy that reduces waste and minimizes the environmental footprint of manufacturing.

How It Works

Material Collection

We start by collecting used metal powders or end-of-life components directly from your facility, ensuring a seamless transition to the reclamation process.

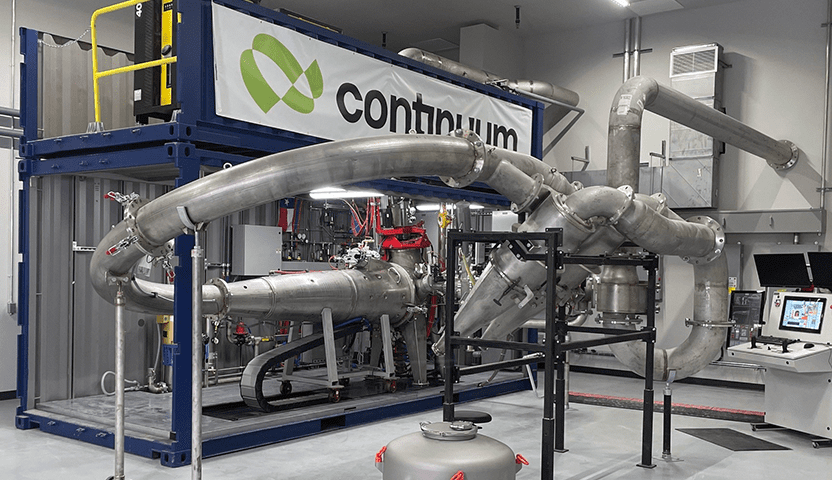

Proprietary Melt-to-Powder (M2P) Technology

Our Greyhound M2P system reclaims & reprocesses metal feedstock in a single step, producing high-quality powder with uniform size, spherical shape, and optimal flowability that meets or exceeds industry standards.

Green Energy & Sustainable Practices

We utilize green energy and eco-friendly argon gas to reduce emissions and achieve near-zero waste. Our commitment to sustainability ensures reclaimed powders are as environmentally responsible as they are high performing.

Rigorous Quality Testing

Each batch of reclaimed powder undergoes stringent quality checks to confirm that it meets the necessary specifications for strength, ductility, and impact resistance. We ensure that the reclaimed powder is indistinguishable from, or even superior to, virgin material.

Closed-Loop Integration

The reclaimed powder is then delivered back to your facility, ready for use in new production cycles. Our closed-loop system not only extends the lifecycle of your materials but also reduces the need for virgin raw material sourcing.

The Benefits of Our Reclamation Process

Environmental Impact Reduction

Minimize reliance on virgin materials and reduce your carbon footprint

Cost Efficiency

Lower costs associated with raw material procurement and waste disposal

Quality Assurance

Enjoy the same high performance and consistency as you would with traditionally sourced metal powders

By choosing Continuum Powders’ reclamation process, you’re not just enhancing your manufacturing capabilities — you’re taking a proactive step towards a more sustainable and responsible future.

Seeing is Believing

Ready to Move Forward?

Request a Powder Sample