This summary highlights key insights from an in-depth article by Sunil Badwe, VP of R&D at Continuum Powders.

Manufacturing is taking a big step toward sustainability with groundbreaking plasma-assisted gas atomization technology that recycles scrap metals into premium-quality metal powders. Developed initially for military and aerospace applications, this single-step process turns industrial waste, such as machining chips, discarded parts, and metal scraps, directly into ASTM-spec metal powders suitable for additive manufacturing (AM), metal injection molding (MIM), hot isostatic pressing (HIP), and other industrial applications.

Recent tests conducted by Oregon State University revealed that this innovative technology reduces the carbon footprint of metal powder production by more than 99% compared to traditional methods. Unlike traditional processes relying heavily on mined ores and energy-intensive production methods, this sustainable approach exclusively uses reclaimed metals, eliminating the need for virgin ores altogether.

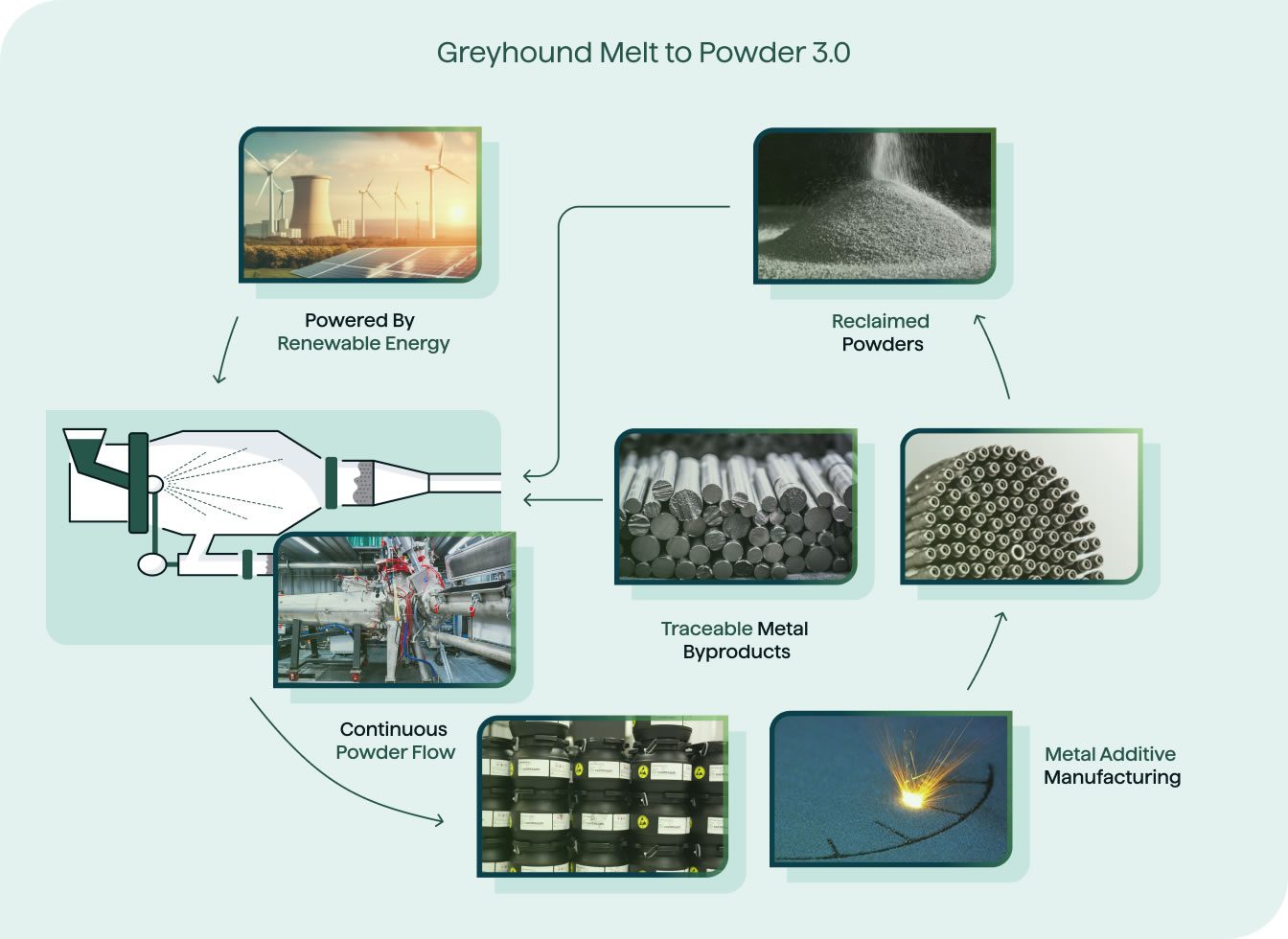

A sustainable, melt-to-powder process supports a circular metal economy, which can lower effective costs, increase speed and reliability of supplies, and reduce carbon and energy use.

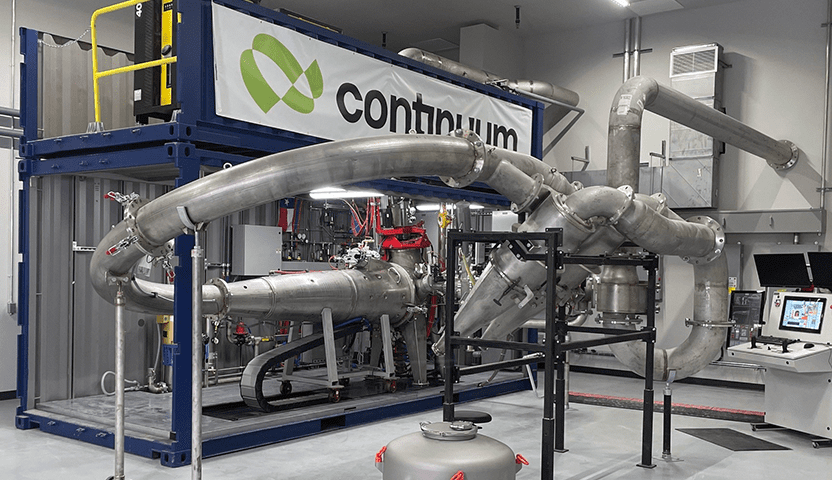

What makes this technology especially transformative is its portability and efficiency. Originally developed for battlefield repairs by the U.S. military, it has been commercialized into compact, shipping-container-sized units capable of producing over 20 tons of high-quality metal powder per month. This adaptability enables manufacturers to recycle metals on-site, significantly reducing logistics costs, supply chain risks, and delays.

Moreover, the versatility of the plasma-assisted process allows precise control over particle size distribution, accommodating various industrial requirements—from fine powders used in laser-based 3D printing (LPBF) to coarser powders for HIP applications.

Economically and environmentally, this approach aligns with growing demands for sustainable business practices. Recycling metals conserves natural resources, dramatically reduces greenhouse gas emissions, and saves significant energy compared to traditional metal extraction processes. Despite these clear benefits, significant portions of metal scrap still end up in landfills due to lack of economical recycling methods. This new technology addresses that gap head-on.

Continuum Powders’ Greyhound Melt to Powder (M2P) platform is an advanced plasma-assisted atomization system that transforms reclaimed metal alloys into high-quality, sustainable metal powders suitable for advanced manufacturing technologies, including additive manufacturing.

Companies integrating this technology into their operations could see substantial financial and environmental benefits, such as cost savings from reclaimed alloys, reduced reliance on foreign mineral imports, eligibility for carbon credits, and alignment with Environmental, Social, and Governance (ESG) goals.

In essence, plasma-assisted atomization technology doesn’t just promise sustainability—it delivers a practical, profitable solution for the future of metal manufacturing, driving forward what experts are now calling the “circular metal economy.”

To explore this technology further, Click here to read the complete article in ASTM International’s Advanced Materials & Process Magazine. Originally published on March 13, 2025.