Global metal supply chains are under increasing pressure. Rising material costs, geopolitical tensions, and supply disruptions have made it harder for manufacturers to source the metals they need at stable prices. At the same time, industries like aerospace, energy, and automotive are demanding more sustainable solutions to meet environmental regulations and carbon reduction goals.

Reclaimed metal powders offer a way forward. By using high-quality, recycled metal feedstock instead of relying solely on newly mined materials, manufacturers can create a more resilient, cost-effective, and environmentally friendly supply chain.

Why Traditional Metal Supply Chains Are Struggling

The traditional metal supply chain depends heavily on mining, refining, and global transportation. This system is vulnerable to multiple risks:

- Geopolitical Instability – Trade restrictions, sanctions, and regional conflicts can limit access to critical raw materials, causing price volatility and shortages.

- Supply Chain Disruptions – Events like the COVID-19 pandemic exposed weaknesses in global logistics, leading to delays and production stoppages.

- Environmental and Regulatory Pressures – Mining and refining processes generate significant emissions and waste, pushing governments to enforce stricter regulations.

- Rising Costs – The price of raw metals, including nickel, titanium, and cobalt, has fluctuated dramatically, making long-term planning difficult for manufacturers.

With these challenges mounting, industries are looking for alternative ways to secure metal feedstock while maintaining quality and performance.

How Reclaimed Metal Powders Strengthen Supply Chains

Reclaimed metal powders provide a viable solution to these supply chain issues. Instead of depending on newly mined metals, manufacturers can use recycled powders sourced from end-of-life components, industrial scrap, and byproducts from existing processes.

- Supply Stability and Reduced Volatility

Reclaimed powders reduce reliance on raw material imports, helping manufacturers mitigate risks associated with geopolitical instability and market fluctuations. With a consistent domestic supply of high-quality powders, companies can better control costs and avoid delays caused by shortages.

- Sustainability and Lower Carbon Footprint

Producing reclaimed powders uses significantly less energy than refining virgin metals, cutting both emissions and waste. This helps companies align with global sustainability initiatives and meet stricter environmental regulations. Additionally, using recycled materials supports circular economy practices, keeping valuable metals in circulation rather than discarding them as waste.

- Cost Savings and Material Efficiency

Reclaimed powders can lower overall production costs by reducing dependence on expensive raw materials. Because additive manufacturing techniques like binder jetting and LPBF use near-net-shape processes, they further minimize waste, making the most out of every gram of material.

- High Performance Without Compromise

Advances in powder processing technology ensure that reclaimed metal powders meet or exceed the quality and performance of virgin materials. Aerospace, medical, and energy industries can confidently use these powders without sacrificing mechanical properties, reliability, or durability.

Industries Benefiting from Reclaimed Metal Powders

Aerospace

Aerospace manufacturers face strict regulations on material sourcing and sustainability. Reclaimed metal powders allow them to meet these requirements while maintaining the high strength and heat resistance needed for components like turbine blades and structural parts.

Energy

The energy sector, particularly in gas turbines and renewable energy applications, relies on nickel and cobalt-based superalloys. Reclaimed powders provide a steady, cost-effective source of these materials without the environmental impact of virgin metal extraction.

Medical

Medical manufacturers use titanium and stainless steel for implants and surgical tools. By integrating reclaimed powders, they can improve supply reliability while meeting stringent biocompatibility standards.

Continuum Powders: Pioneering Sustainable Metal Powders

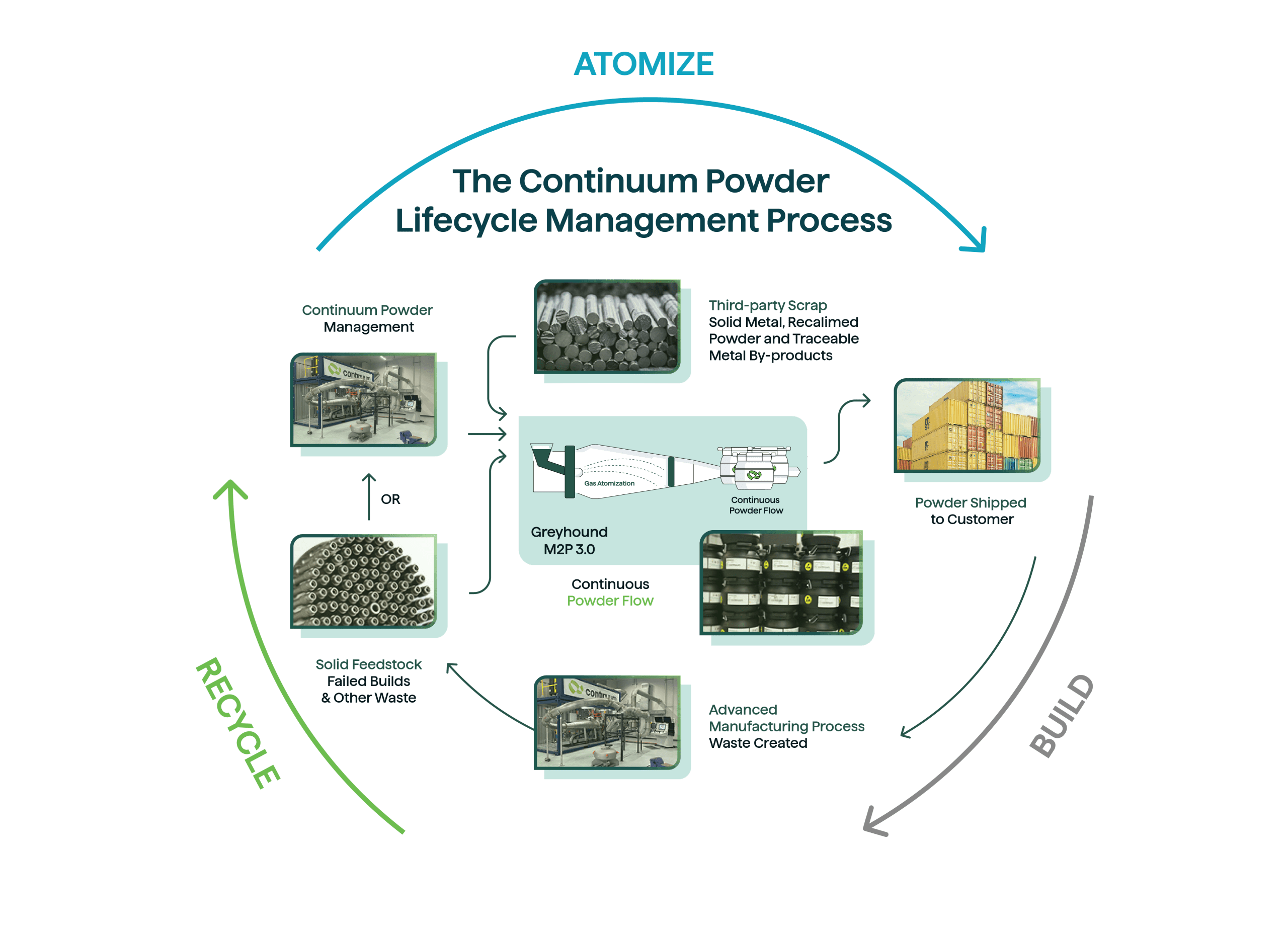

Continuum Powders is at the forefront of this shift toward sustainable, high-performance reclaimed powders. Our Melt-to-Powder (M2P) technology transforms industrial scrap and end-of-life components into premium-quality spherical powders suitable for additive manufacturing. Contiuum OptiPowders are compatible across various AM platforms, giving manufacturers the flexibility to innovate with ASTM-grade powders and reduce their environmental footprint.

By choosing reclaimed powders, manufacturers not only secure a more stable and cost-effective supply chain but also take a meaningful step toward a more sustainable future.

The Future of Resilient Metal Supply Chains

The global metal supply chain is evolving, and reclaimed powders are playing a crucial role in that transformation. As industries push for greater sustainability, cost stability, and supply chain security, reclaimed metal powders offer a smart alternative to traditional sourcing. Investing in these materials today will help manufacturers stay competitive, adaptable, and aligned with the future of responsible production.