In the rapidly evolving world of advanced manufacturing, sustainability and innovation are no longer just buzzwords—they are essential drivers of progress. At Continuum Powders, we are at the forefront of this movement, harnessing cutting-edge technology and sustainable practices to redefine what’s possible in metal powder production.

Who We Are

Continuum Powders is a leading provider of sustainable premium metal powders designed for additive manufacturing (3D printing) and other high-performance applications. We specialize in converting reclaimed materials into valuable, reusable powders, offering a sustainable alternative to traditional metal production methods. Our innovative approach, powered by green energy, makes us a standout in an industry that is increasingly focused on sustainability.

Central to our operations is the Greyhound M2P 3.0 powder atomizer—our proprietary technology that allows for efficient and continuous production of metal powders. This system gives us the flexibility to produce a variety of metal powders, all while minimizing our carbon footprint.

What We Offer

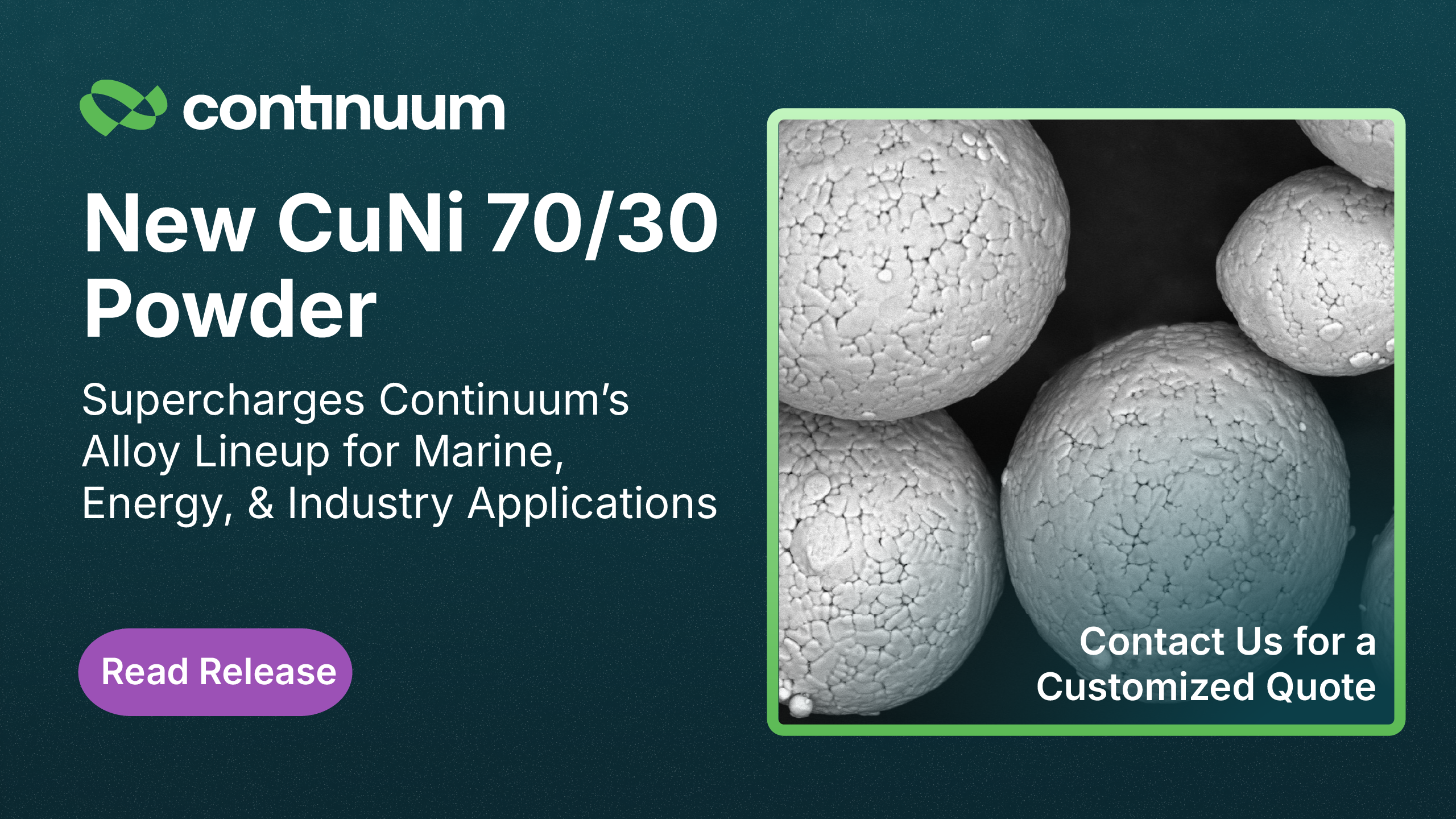

At Continuum, we provide a wide range of metal powders to meet the diverse needs of industries like aerospace, automotive, defense, and medical. Our portfolio includes Ni718, Ni625, 316 stainless steel, 17-4 stainless steel, and maraging steel, with titanium soon to be added. We offer custom powder grades, working directly with clients to tailor powders to their specific requirements.

What’s more, we provide a unique service where we collect your unused materials–whether it’s failed parts, excess powder, or post-processing byproducts–reclaim them, and return them to you as ASTM-grade powder. This ensures that you strategically utilize unused materials and reduce costs. By closing the loop on material usage, you also get the added benefit of contributing to a more sustainable manufacturing process. With Continuum’s service, you gain the confidence in using high-quality, certified materials while minimizing your environmental impact and optimizing your producing efficiency.

But our commitment doesn’t stop at product offerings. We pride ourselves on delivering ongoing support to optimize resource use and help manufacturers meet their sustainability targets. Whether it’s finding the right powder for a specific application or developing custom alloys, we work closely with our customers to ensure their success.

Innovation at the Core: The Greyhound M2P 3.0 Atomizer

At the heart of our operations is the Greyhound M2P 3.0 powder atomizer, a forward-thinking technology in the world of metal powder production. This system uses a DC plasma heat source to process small batches of various alloys, enabling companies to test or produce different metals using the same machine. Its ability to operate continuously makes it ideal for companies looking to maintain flexibility in their manufacturing processes.

The Greyhound M2P 3.0 is more than just an atomizer—it’s a critical tool for advancing localized production. This means that businesses, cities, or even countries can recycle previously used metal material on-site, turning it into usable metal powders. By doing so, Continuum enables self-sufficiency while reducing reliance on global supply chains, cutting transportation costs, and mitigating logistical delays.

A Commitment to Sustainability

At Continuum Powders, sustainability is not just part of our mission—it’s embedded in every step of our production process. From using 100% recycled feedstock to harnessing green energy and eco-friendly atomization gases like green argon, we aim for a nearly carbon-zero footprint.

Our emphasis on circularity ensures that waste materials, such as scrap metals and machine turnings, are transformed into high-quality powders that can be used again and again. This not only reduces the need for new raw material extraction but significantly lowers energy consumption, making our processes far more sustainable than traditional manufacturing methods.

Setting Ourselves Apart

What truly sets Continuum Powders apart is our commitment to sustainability, circularity, and innovation. While other powder producers may focus on large-scale, traditional production, we are pioneering a new way forward—one that integrates environmental responsibility with technological advancement.

Our materials are produced by reclaiming alloyed metal waste-stream products into powder in a single processing step. This approach eliminates the need for extensive transportation, product handling, primary melting, and lengthy bar processing operations, all while reducing the demand for mining raw elemental metals from the Earth.

Our localized production model allows customers to recycle their existing materials, giving them a sustainable, cost-effective way to produce high-quality powders. This model also reduces the need to rely on external suppliers, offering greater supply chain security—a key consideration in today’s globally disrupted market.

The Industries We Serve

We serve a broad range of industries, including aerospace, automotive, defense, and medical—all of which demand high-performance materials for critical applications. Our powders are produced to meet the stringent requirements of these sectors, ensuring that they are both sustainable and of the highest quality. Whether for additive or other advanced manufacturing processes, our powders deliver the performance these industries require.

Customization to Meet Your Needs

One of our key differentiators is our ability to provide custom alloy powders. We understand that no two manufacturing processes are the same, which is why we work closely with our clients to develop powders tailored to their specific needs. Our expert team collaborates with customers to ensure compatibility with different applications, delivering a truly personalized solution.

High-Quality Standards

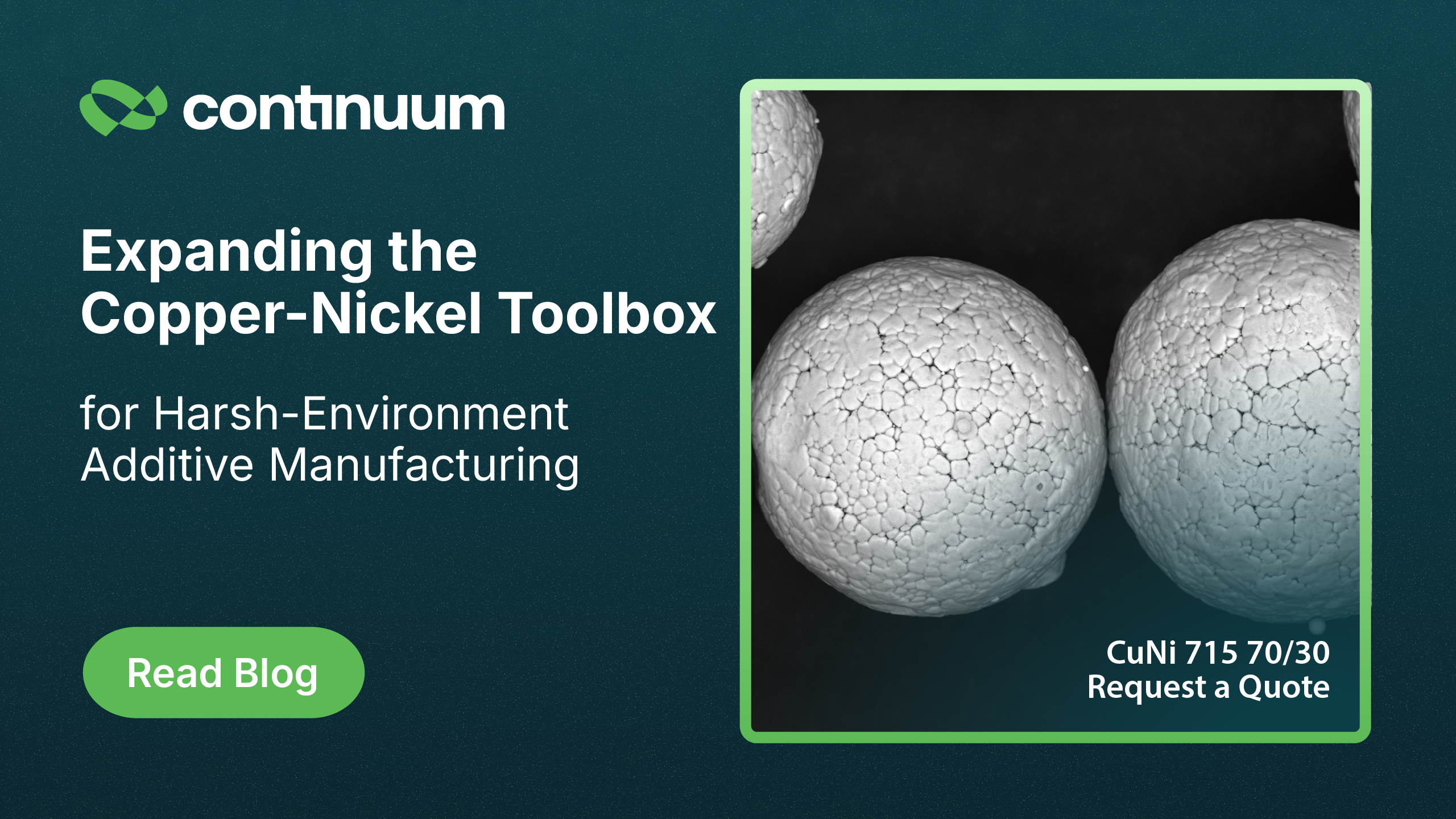

When it comes to quality, Continuum Powders adheres to the highest industry standards. Our powders undergo rigorous testing to ensure purity, consistency, and performance. We utilize advanced atomization techniques and continuously monitor our production process to guarantee uniform particle size and spherical shape—both critical factors for success in additive manufacturing. Our commitment to quality control means our customers can rely on our powders to deliver consistent results every time.

Looking Ahead

At Continuum Powders, we believe that the future of manufacturing lies in sustainability and innovation. By continuing to develop cutting-edge technologies like the Greyhound M2P 3.0 and expanding our range of high-quality, sustainable metal powders, we are poised to lead the metal powder industry into the next era of manufacturing.

As industries increasingly prioritize environmental responsibility, Continuum Powders is committed to providing the solutions they need to reduce their carbon footprint, enhance resource efficiency, and build a more sustainable future. Together, we can shape a world where technology and sustainability go hand in hand.

Let us know how we can help your business achieve its sustainability goals with high-performance, eco-friendly metal powders. At Continuum Powders, innovation and sustainability are in our DNA.